Arduino power strip: More enclosure & more wiring

Visit this project on GitHub.

This post is part of a series:- Building an Arduino-controlled power strip

- Arduino power strip: More enclosure & more wiring

- Arduino power strip: Finishing touches, problems, and future improvements

Time for an update on the Arduino-controlled power strip! In the last post I described how I built the front plate with the outlets and did a bit of wiring—in this post we will do more of that and be able to even test it for the first time.

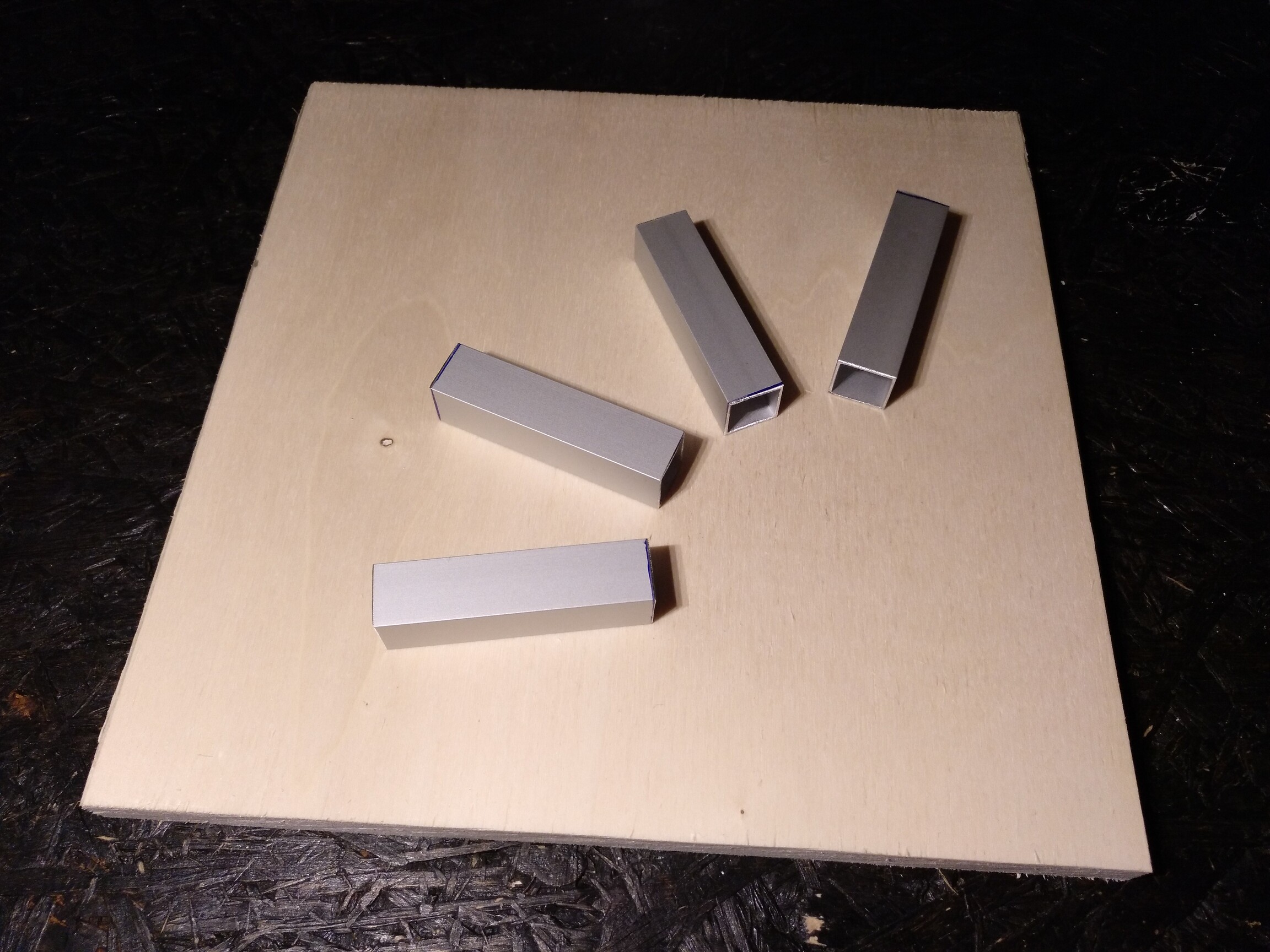

First, I cut the 220 × 220 mm (≈ 8 1/2″ × 8 1/2″) back plate from 12 mm (≈ 1/2″) plywood and four 60 mm (≈ 2 1/2″) pieces of 15 mm (≈ 5/8″) aluminum square profile. You don’t need fancy tools for that, a small “Puk Saw” as shown in the picture works fine. I used thicker wood than for the front plate to be able to screw into it more easily for mounting stuff.

Then I drilled one 6.5 mm (≈ 1/4″) diameter 8 mm (≈ 5/16″) deep hole in each of the four corners of the back plate and screwed in M4 threaded inserts.

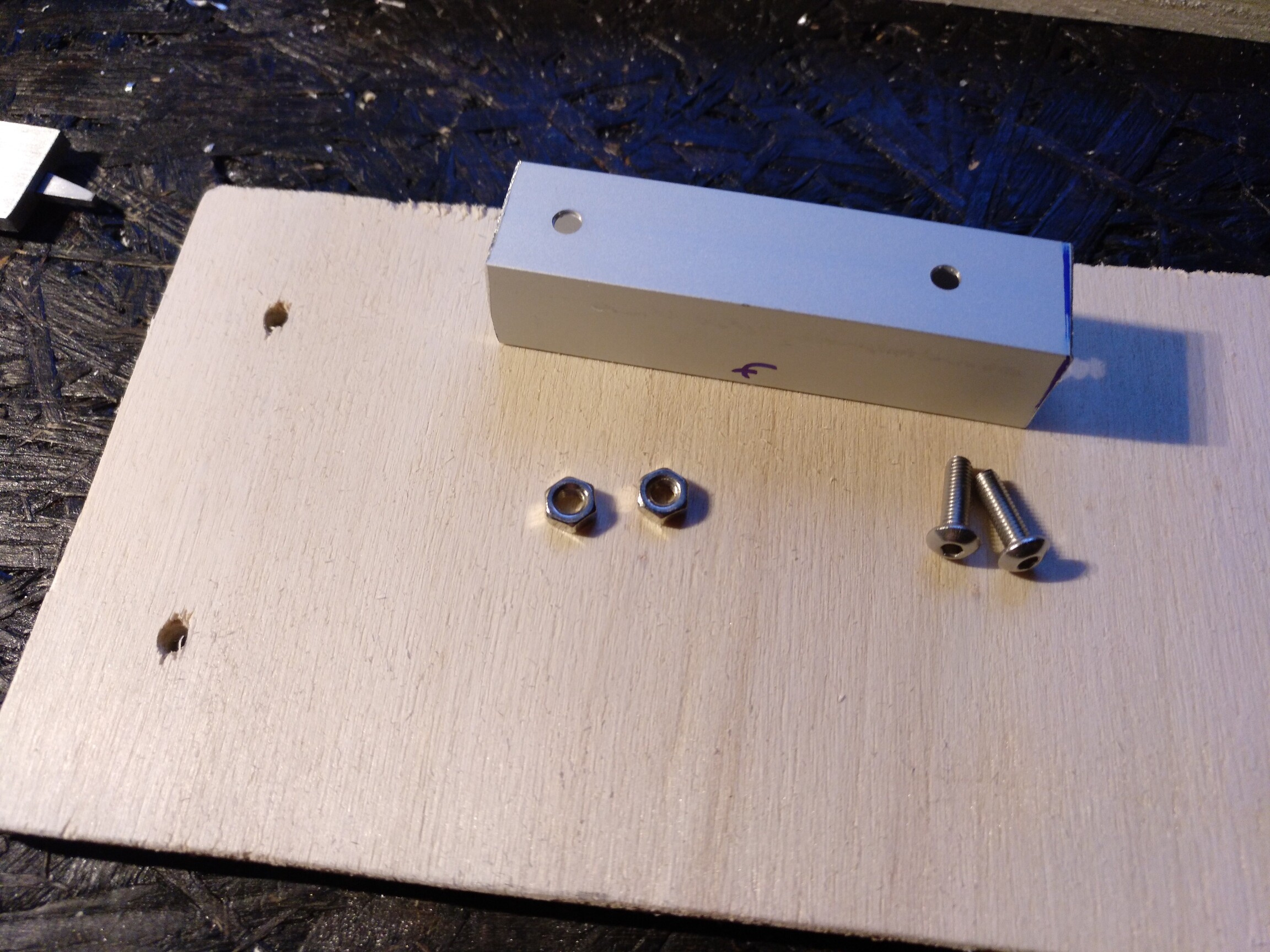

To connect the front plate with the back plate, I used M4 threaded rod, from which I cut four 78 mm (≈ 3″) pieces, together with cap nuts. You can also use simple screws, but I had the threaded rod and the cap nuts lying around from another project so I used that.

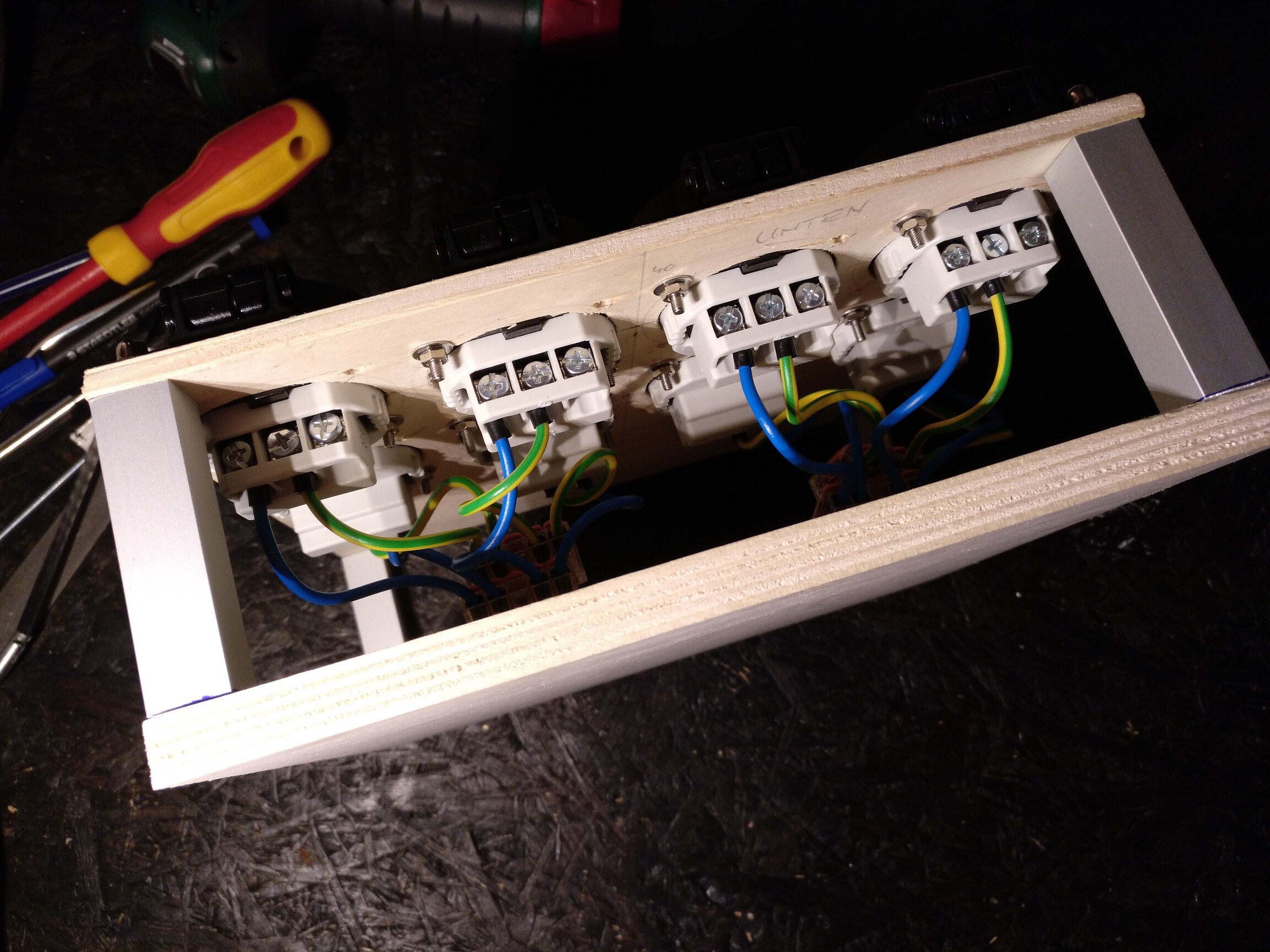

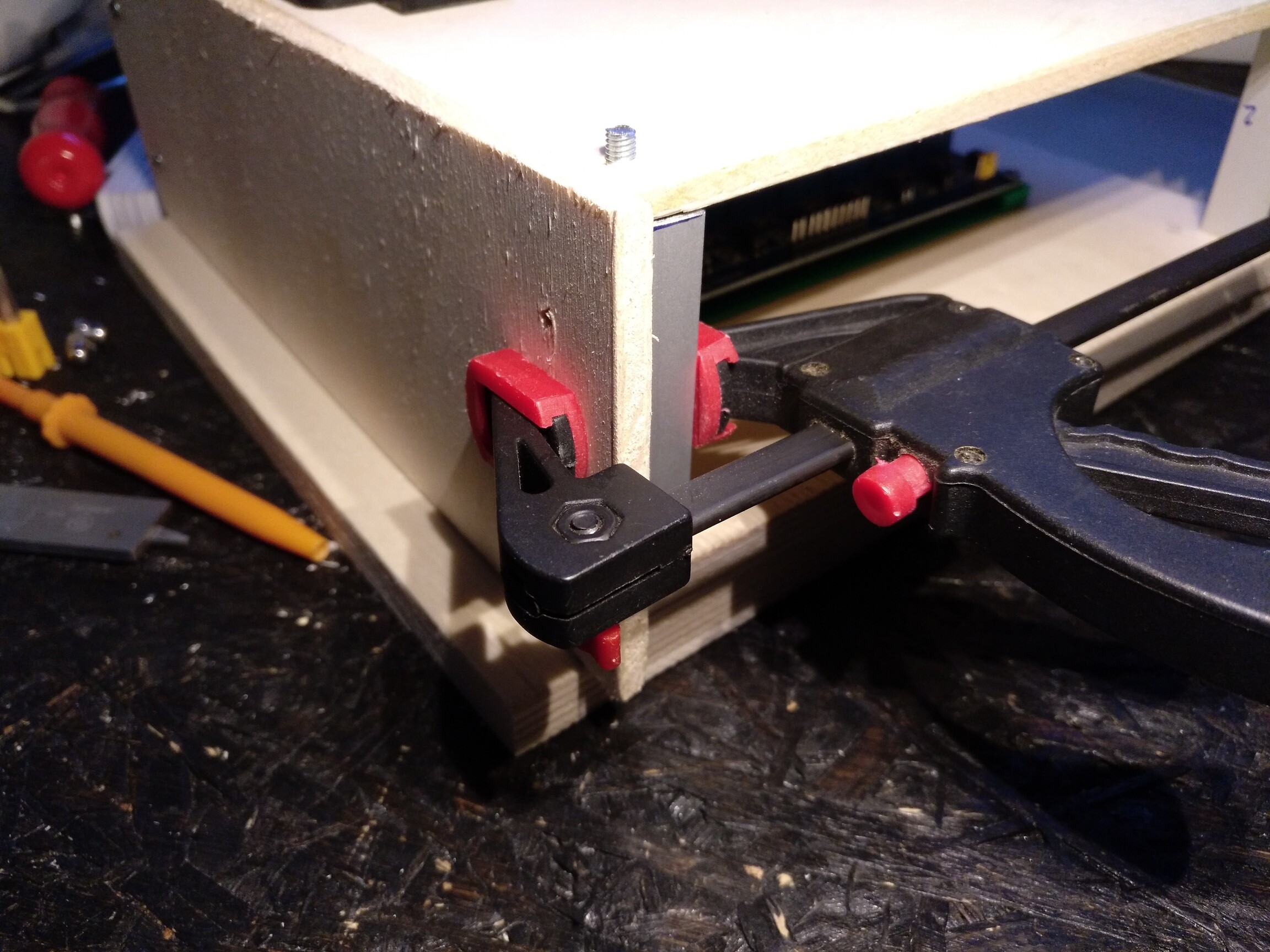

After drilling matching 4 mm (≈ 5/32″) holes in the front plate, I connected it to the back plate using the threaded rods and aluminum profiles as spacers. It’s starting to take shape…

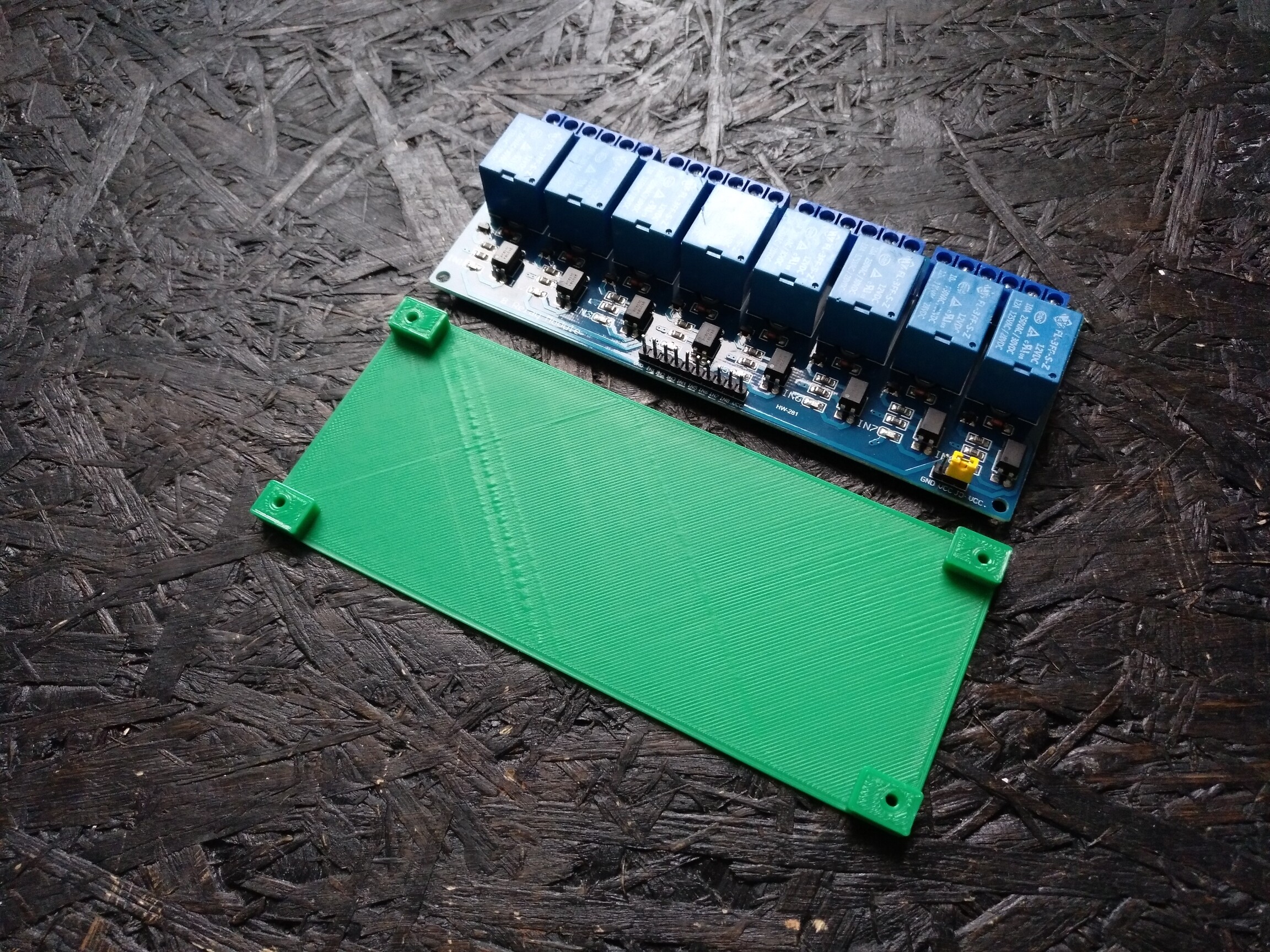

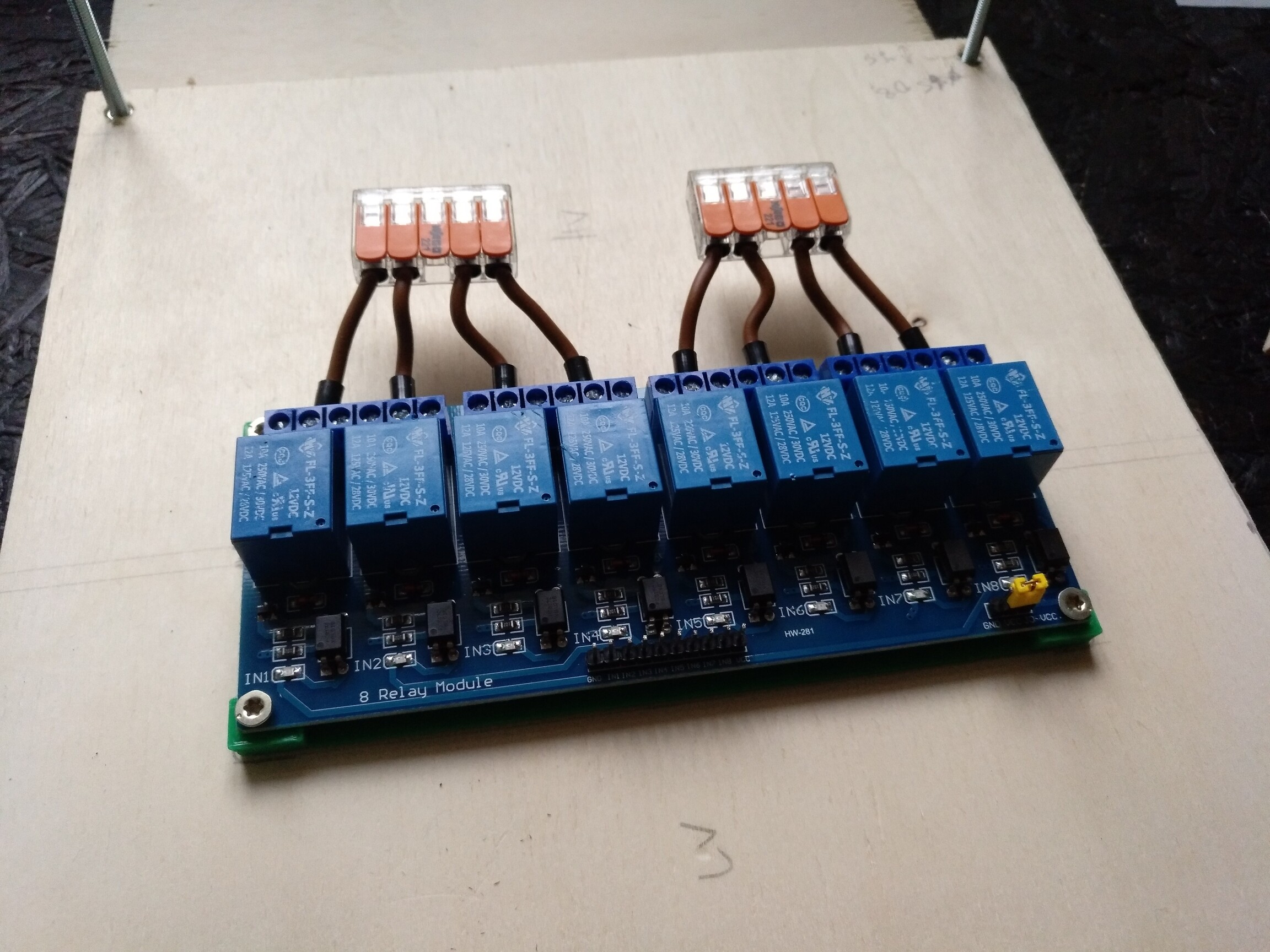

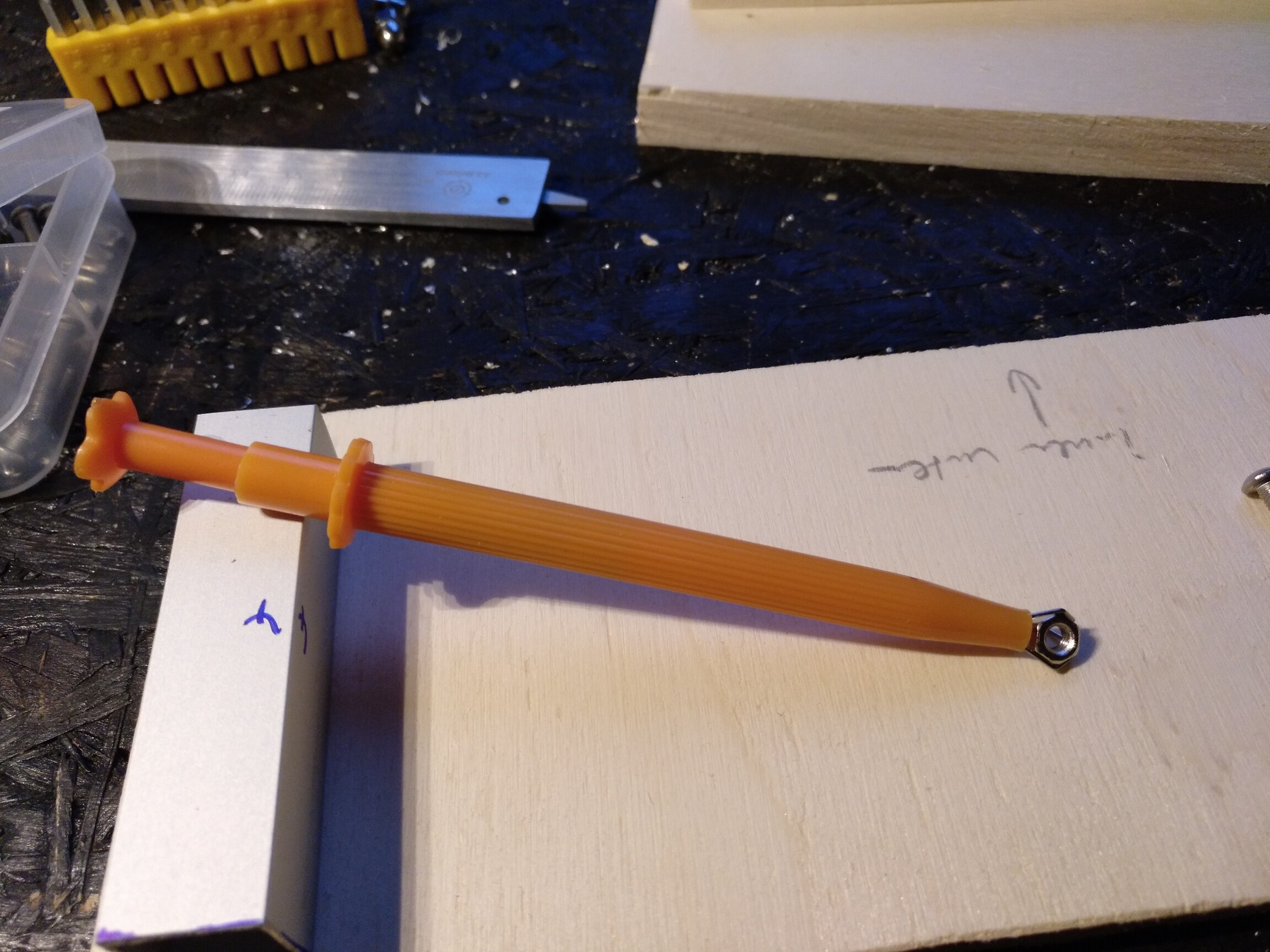

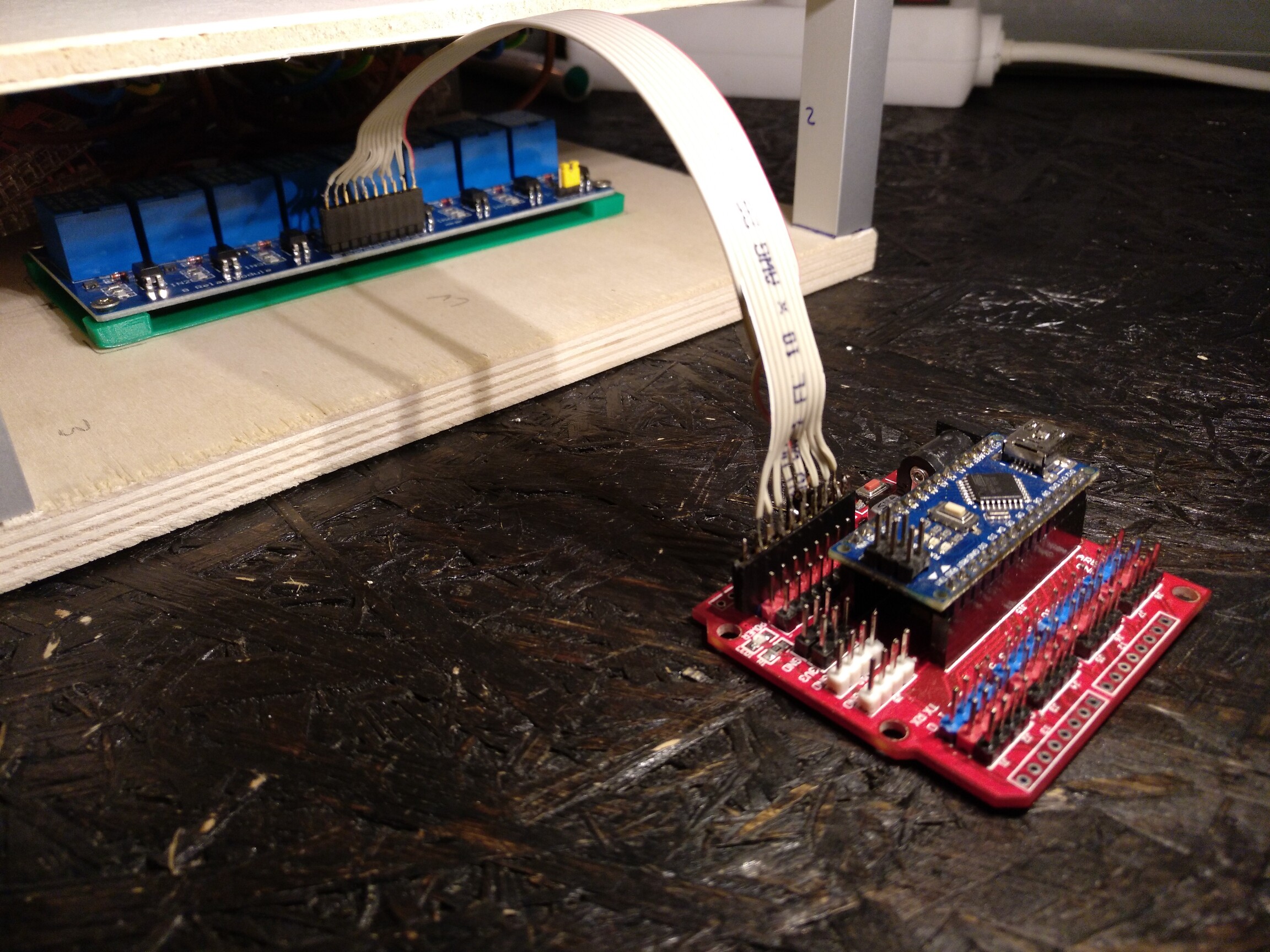

After this first test fitting I took it back apart and mounted the relay module to the back plate using a 3D-printed holder and 3 × 16 mm (≈ 1/8″ × 5/8″) wood screws. The OpenSCAD file for the holder is on GitHub, but simple spacers should work fine, too. I have a 3D printer sitting on my bench, so I’m always searching for excuses to use it…

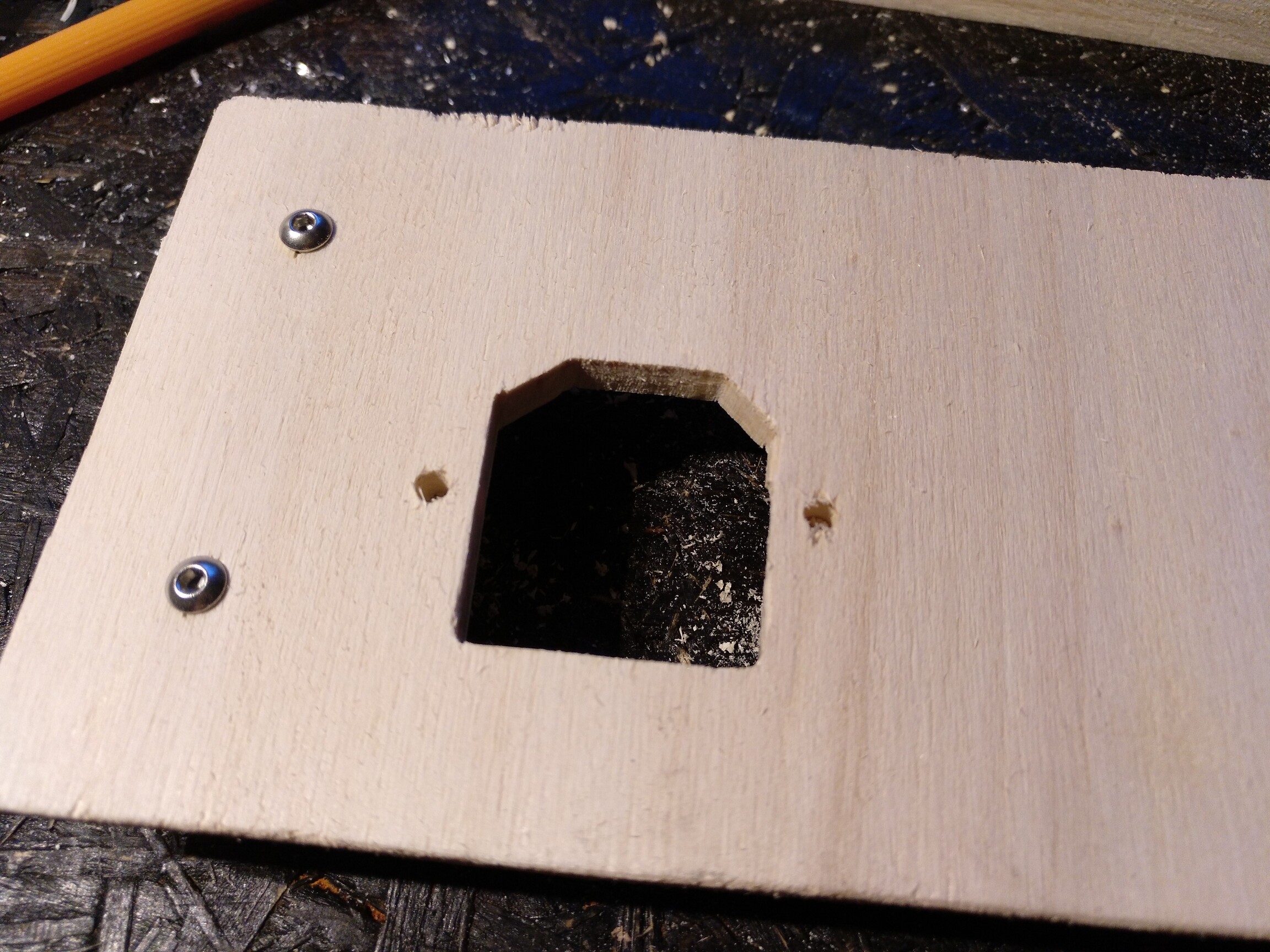

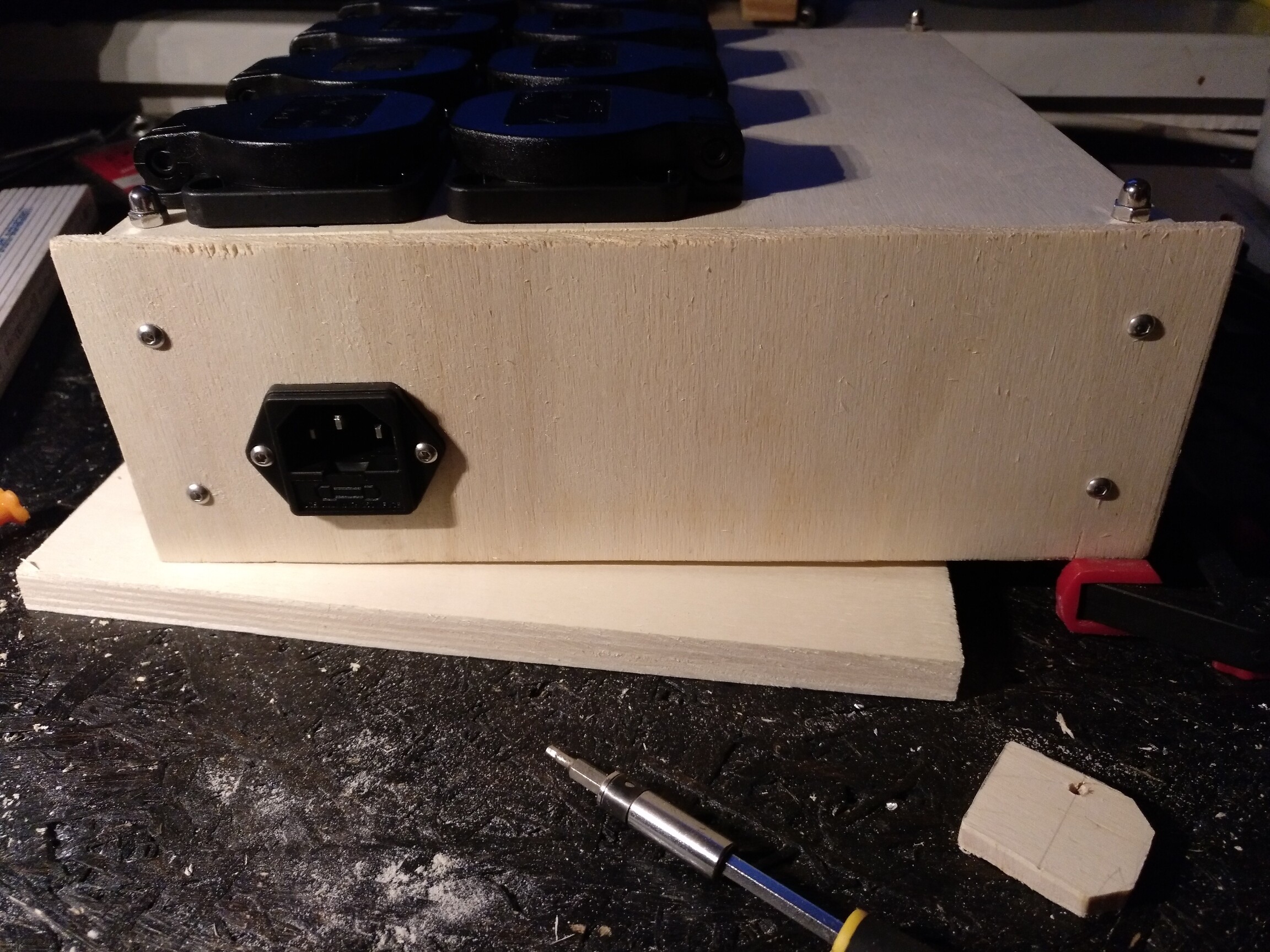

To be able to mount the power input connector, I then cut the first 235 × 80 mm (≈ 9 1/2″ × 3″) side panel from 6 mm (≈ 1/4″) plywood, drilled 3 mm (≈ 1/8″) holes 15 × 20 mm (≈ 5/8″ × 3/4″) from the edge for mounting screws, and transferred them to the aluminum profiles.

I then mounted the aluminum extrusions to the side panel using 10 mm (≈ 3/8″) M3 screws and nuts, which was a bit tricky because of the tight space. The weird grabber tool you see on the picture was very helpful to hold the nuts.

After sawing a hole for the power input connector using a scroll saw and drilling two 3 mm (≈ 1/8″) holes, I was able to mount the connector using 12 mm (≈ 1/2″) M3 screws and nuts.

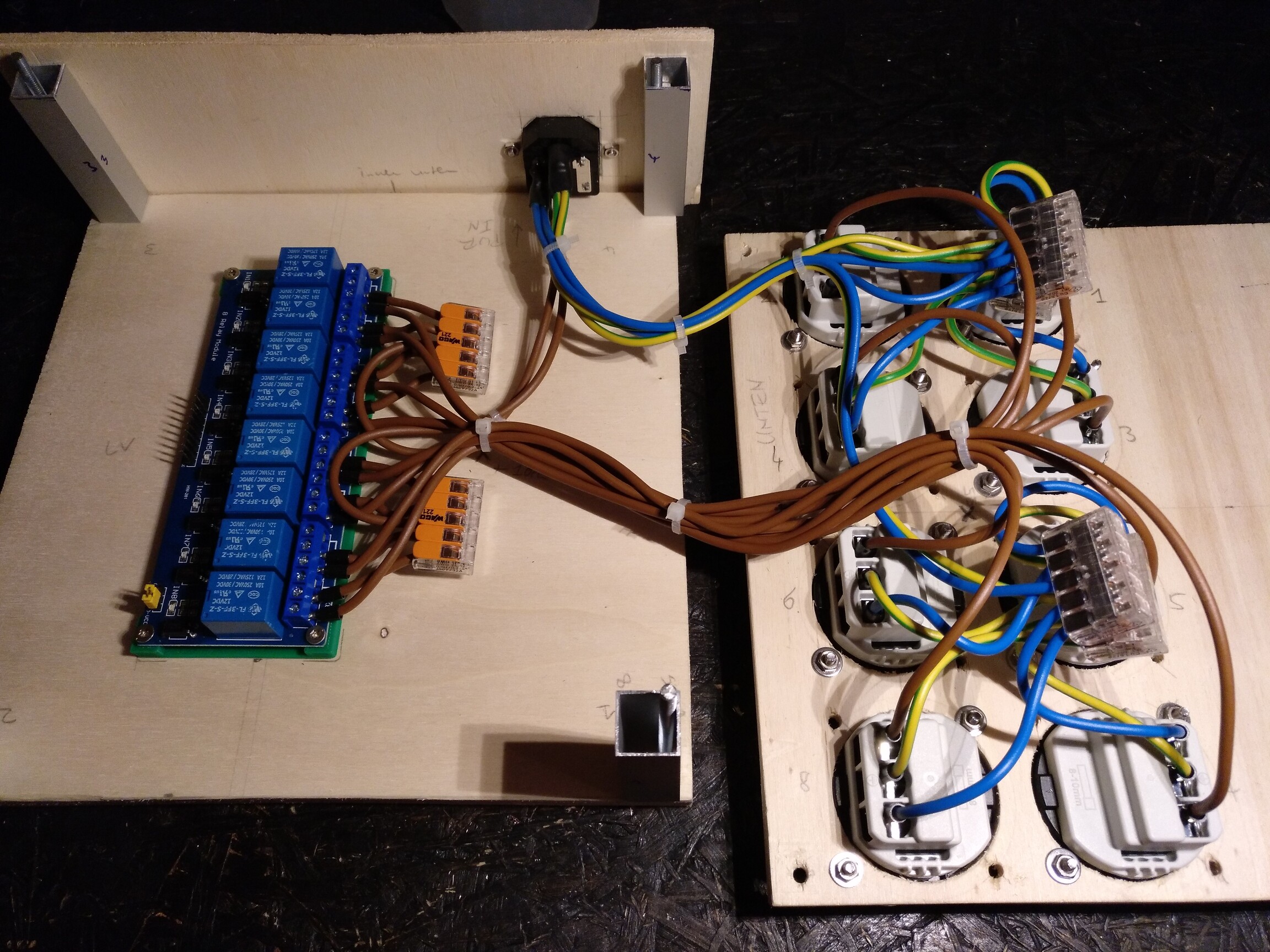

With the power connector mounted, I finished the “high voltage” wiring by connecting the neutral and ground from the connector to the outlets, the live connection from the connector to the relay board, and the relay board outputs to the outlets.

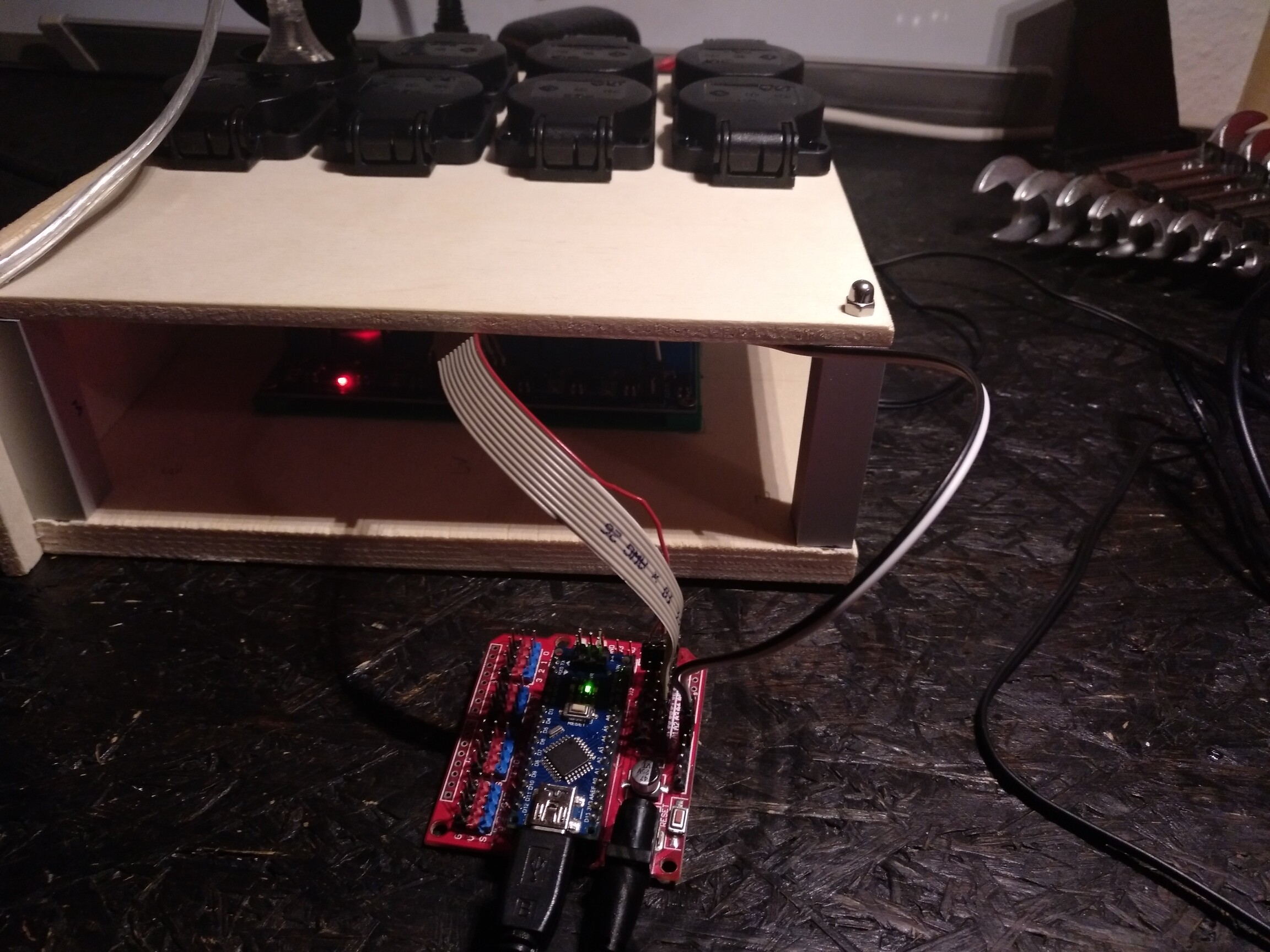

After screwing the top plate and the back plate together again, I just had to connect an Arduino Nano and was able to test it for the first time. And… it didn’t work. Turns out you need to supply the opto-isolators with 5 V and the relays with 12 V—it won’t work if you supply 12 V to both.

After I figured that out, everything worked like a charm. The software is still in development, but already on GitHub. More on that in a later post!

Visit this project on GitHub.

This post is part of a series:- Building an Arduino-controlled power strip

- Arduino power strip: More enclosure & more wiring

- Arduino power strip: Finishing touches, problems, and future improvements